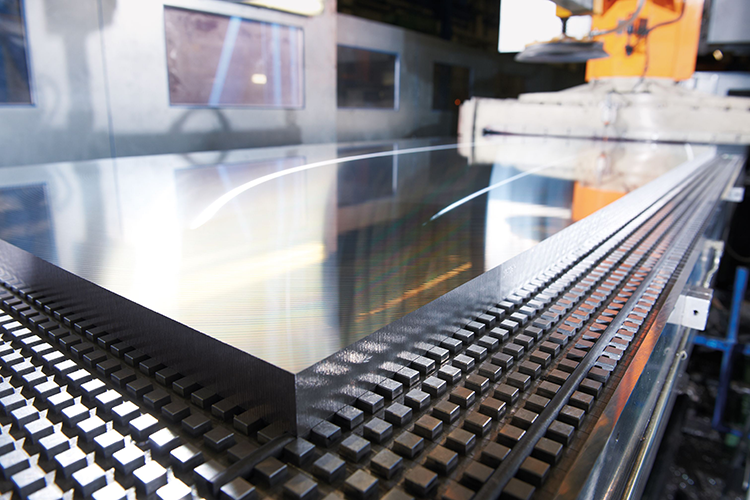

QC-10® expands mold design options and brings new performance capabilities to high volume manufacturing. It machines 8-10 times faster than steel, reducing finishing costs and lead times by 20-30%. Plus it conducts heat nearly 5 times faster than P-20 tool steel, shortening production cycle times by 20-40%.

Specifically designed for high production injection and blow mold applications, QC-10 offers greater strength, stability, and durability than any other high-grade aluminum mold alloy on the market today. Its improved alloy composition provides outstanding, 1″- 24″ thick section strength and hardness equal to that of rolled plate. While its quench insensitive microstructure allows minimal strength drop-off and unequalled machinability.

QC-10: Hot Runner Integration

Hot runner systems can be successfully integrated into aluminum molds. In fact, many hot runner manufacturers are experienced with producing hot runner systems specifically for use in aluminum molds. It is important that the mold and hot runner design take into account the thermal and mechanical properties of aluminum.