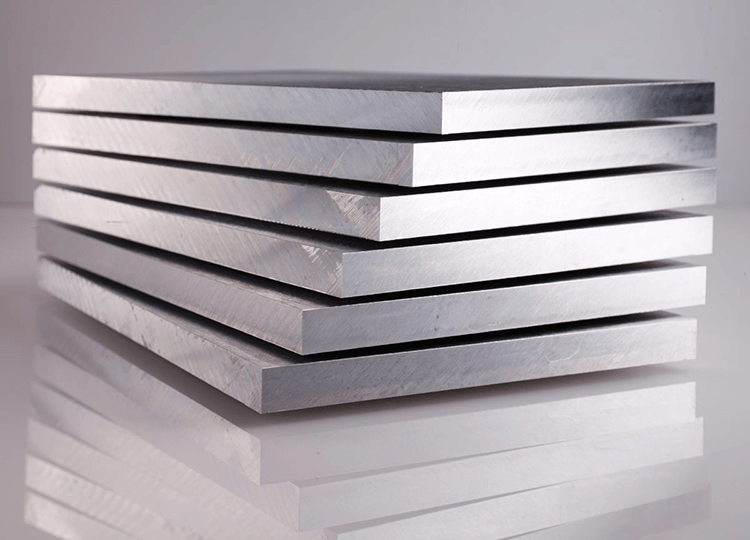

Aluminum Plate

Our aluminum product line has been carefully selected to service a wide range of manufacturing requirements. We offer grades that can service the following applications, Blow Molds, Prototype Molds, Plastic Injection Molds, Thermoforming, and Structural Foam Molds