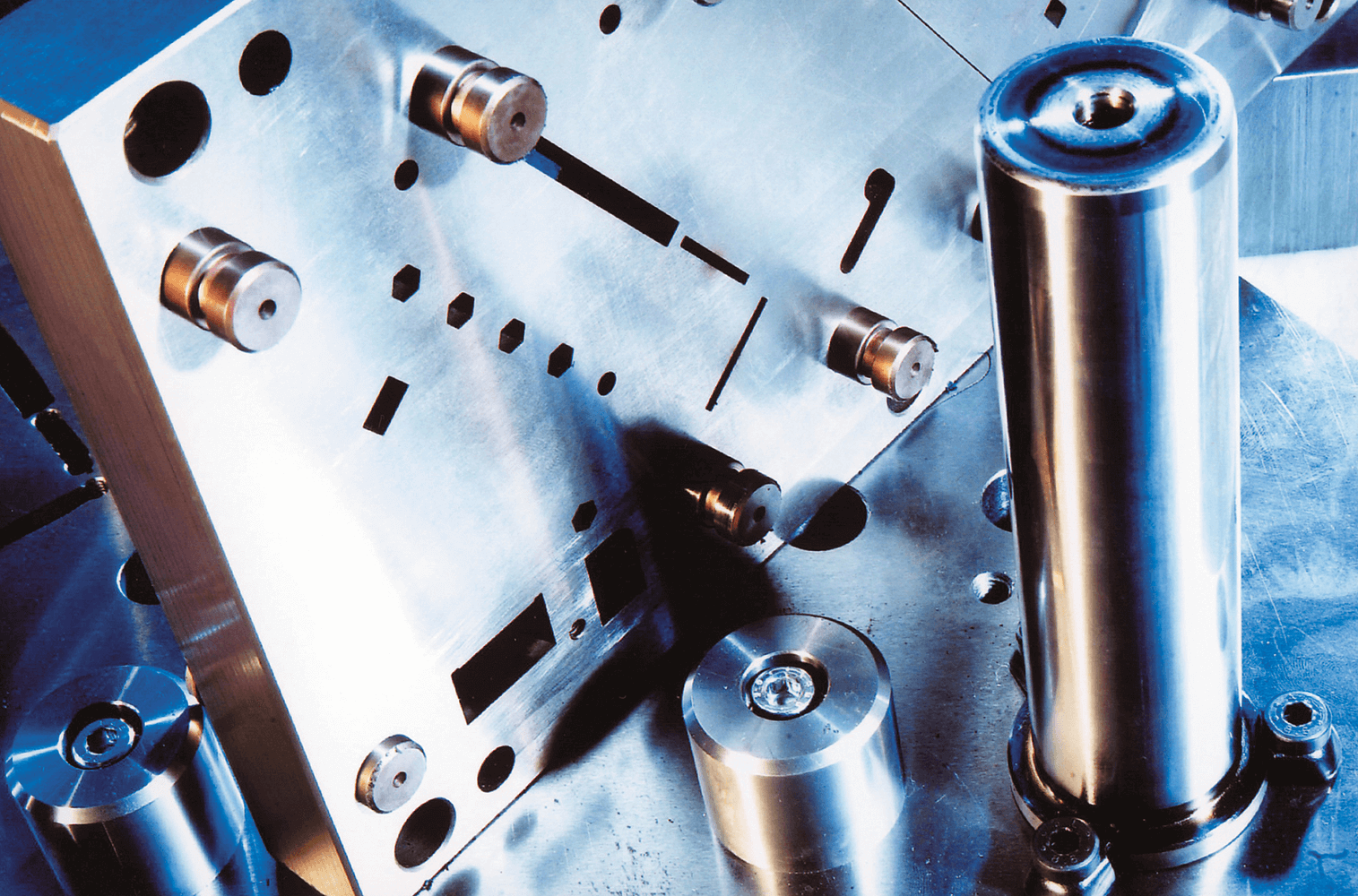

Cold Work Tool Steels

BÖHLER steels are used to produce tools for a variety of cold working applications. High hardness, good ductility, low dimensional changes under heat treatment, and sufficient machinability are the most critical properties of these steels.