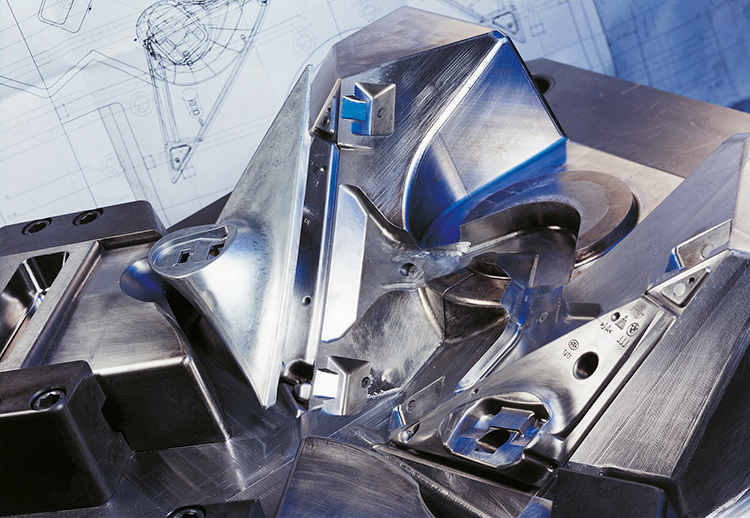

Pressure die casting, forging, and extrusion: when it gets hot, tool steels need to be tough—and especially pure. The special properties of BÖHLER hot-working steels are specifically tuned for high-temperature applications.

High Pressure Die Casting Materials

Böhler Die Casting Concept

We speak customer language and offer taylor made die casting solutions – project by project. The material selection is based on the actual loading condition. We offer improved quality for Böhler die casting materials. We only accept the highest quality standards for heat treatment. With our process- and material know-how, our global network and our state of the art technology we are your full service provider for machining, heat treatment, coating and additive manufacturing powder.

Downloads

Grade | Description | Typical Hardness (HRC) | High Temperature Strength | Wear Resistance | Toughness | Machinability |

Hardenable Steels | ||||||

Premium AISI H13 ESR. | ~52* | |||||

Modified H11 ESR, high toughness in larger cross sections. | ~48* | |||||

Modified H13 ESR, outstanding toughness higher hardness levels. | ~55* | |||||

Modified H11 melted/remelted under vacuum for high toughness. | ~48* | |||||

Vacuum remelted Mod. 1.2367 | ~52* | |||||

Hot work tool steel featuring excellent hot tensile properties, high hot wear resistance, adequate toughness and heat checking resistance; admits water cooling.

Applications

- Heavy duty hot work tools and dies, mainly for light alloy processing: mandrels, dies, and containers for metal tube and rod extrusion.

- Hot extrusion equipment

- Tools and dies for the manufacture of hollow bodies, screws, rivets, ruts, and bolts.

- Die casting equipment, forming dies, die inserts, hot shear blades, and plastic molding dies.

Technical Specifications

High temperature strength

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

Material Numbers

- DIN: 1.2344

- UNS: T20813

- EN: X40CrMoV5-1

- AISI: H13

- STN: 19 554

Executions

- Round Bar

- Saw Cutting

- Flat Plate

- Saw Cutting

- 6 Side Processing

- Surface Grinding

- Gun Drilling

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

Downloads

A balanced alloy composition ensuring high toughness even in large tools and an improved thermal stability opts for an optimal hardness/strength-toughness/ductility ratio (elongation after fracture and percentage reduction of area after fracture) tailor-fit to every application.

Characteristics

- Excellent toughness

- Great through-harden-ability

- Good wear resistance

Technical Specifications

High temperature strength

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

Applications

- High Pressure Die Casting

- Forging

- Hot Stamping

Executions

- Flat Plate

- Saw Cutting

- 6 Side Processing

- Surface Grinding

- Gun Drilling

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

Downloads

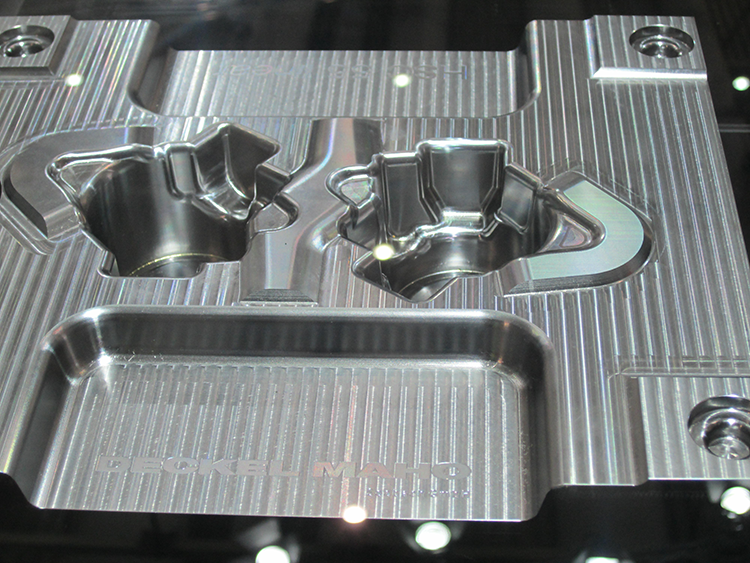

Hot work tool steel with high hardness, specially developed for use in warm forging applications or for forging dies. BÖHLER W360 ISOBLOC has a significantly higher toughness than 1.2367 ESR – at a higher hardness.

BÖHLER W360 ISOBLOC is widely used in all high wear / high toughness requirement situations in forging, plastic injection, heavy duty stamping and much more.

Characteristics

- High hardness (recommended in use: 52 – 57 HRc)

- Exceptional toughness

- High temper resistance

- Good thermal conductivity

- Can be cooled with water

- Homogeneous microstructure

Technical Specifications

High temperature strength

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

Applications

- Dies and punches in warm and hot forging

- Tooling for high speed presses

- Toughness-critical cold work applications

- Extrusion tooling, e.g. dies

- Core pins and inserts in die-casting dies

- Specific applications in the plastic processing sector

Executions

- Round Bar

- Saw Cutting

- Flat Plate

- Saw Cutting

- 6 Side Processing

- Surface Grinding

- Gun Drilling

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

Downloads

Vacuum remelted hot work tool steel with a good temper resistance, but tougher than W403.

Due to the balanced combination of a modified chemical composition and an optimized processing route, optimum material properties have been achieved in BÖHLER W400 VMR.

Most importantly, BÖHLER W400 VMR’s toughness is higher then any other hot work tool steel available on the market.

Characteristics

- Good macro- and microstructure with lowest levels of segregation

- Lowest gas contents

- Lowest levels of unwanted trace elements

- Excellent homogeneity and isotropy

- Highest degree of cleanliness

- Highest toughness

- Best polishability

- Higher thermal conductivity

Technical Specifications

High temperature strength

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

Applications

- Heavy duty hot work tools and dies, mainly for light alloy processing: mandrels, dies, and containers for metal tube and rod extrusion.

- Hot extrusion equipment

- Tools and dies for the manufacture of hollow bodies, screws, rivets, ruts, and bolts.

- Die casting equipment, forming dies, die inserts, hot shear blades, and plastic molding dies.

Material Numbers

- DIN: ~1.2367

- EN: ~X38CrMoV5-3

Executions

- Round Bar

- Saw Cutting

- Flat Plate

- Saw Cutting

- 6 Side Processing

- Surface Grinding

- Gun Drilling

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

Downloads

Vacuum remelted hot work tool steel with high temper resistance and therefore maximum resistance to heat checking.

BÖHLER W403 VMR addresses the number one failure mode in High Pressure Die Casting, heat checking, and offers the best resistance to premature impact of fatigue.

Characteristics

- Good macro- and microstructure with lowest levels of segregation

- Lowest gas contents

- Lowest levels of unwanted trace elements

- Excellent homogeneity and isotropy

- Highest degree of cleanliness

- Good toughness

- Best polishability

- Best heat checking resistance (resistance to thermal fatigue)

- Very high thermal stability

Technical Specifications

High temperature strength

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

Applications

- Heavy duty hot work tools and dies, mainly for light alloy processing: mandrels, dies, and containers for metal tube and rod extrusion.

- Hot extrusion equipment

- Tools and dies for the manufacture of hollow bodies, screws, rivets, ruts, and bolts.

- Die casting equipment, forming dies, die inserts, hot shear blades, and plastic molding dies.

Material Numbers

- DIN: ~1.2367

- EN: ~X38CrMoV5-3

Executions

- Round Bar

- Saw Cutting

- Flat Plate

- Saw Cutting

- 6 Side Processing

- Surface Grinding

- Gun Drilling

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

Downloads

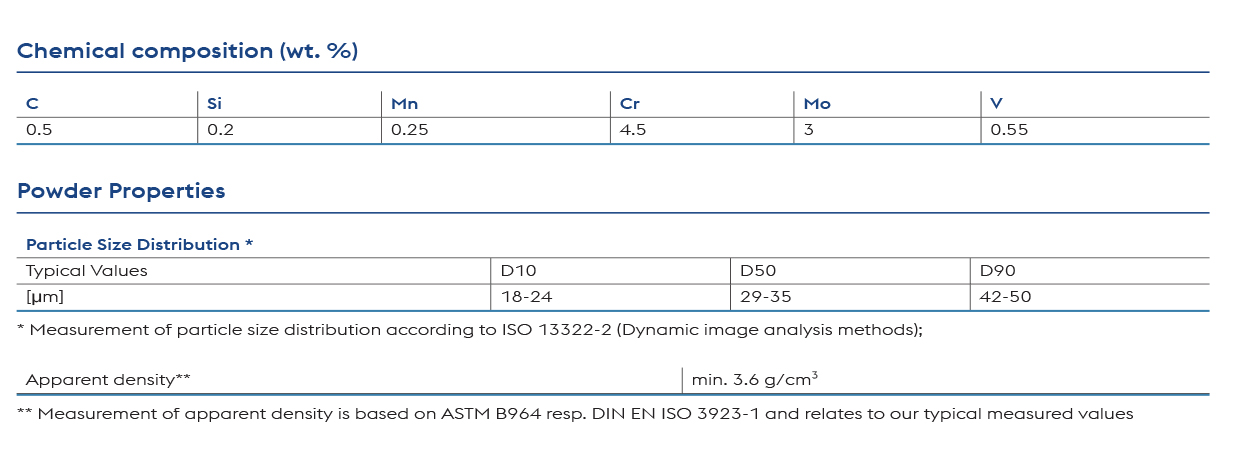

The BÖHLER W360 AMPO is the powder equivalent of the W360 ISOBLOC, a DIN 1.2367 type material. After hardening and tempering, it can achieve a hardness of up to 57 HRC with very good toughness properties. It has high temperature wear resistance, heat resistance and toughness. Applications: Printed components with conformal cooling for die casting applications, wear protection layers and repair work in mold making using laser cladding.

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

Downloads

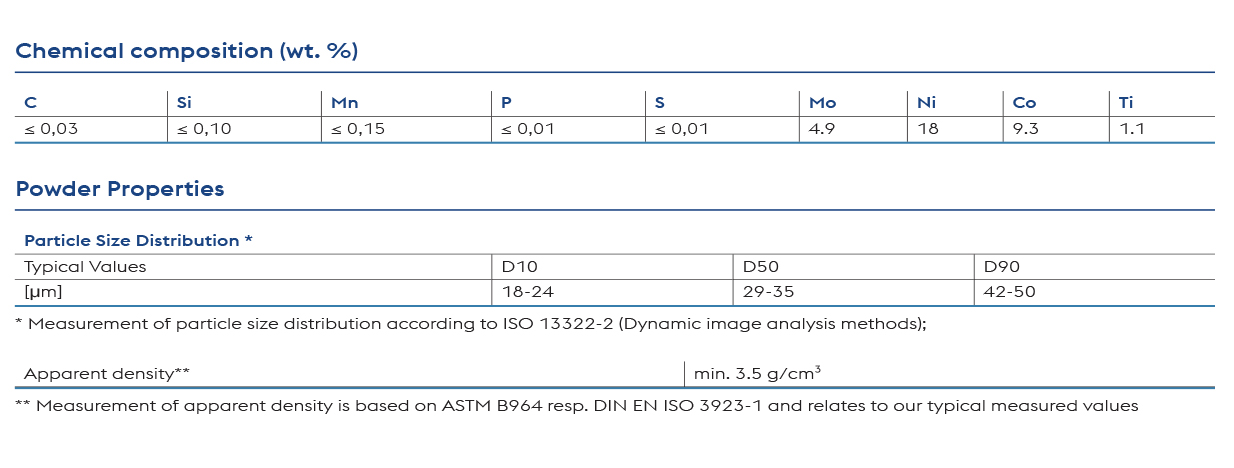

W722 is a maraging 300 type material which offers a good combination of strength and toughness. Can be printed very easily without additional heating of the building platform or chamber. The achievable hardness of 55 HRC makes this material a universal solution for tool steel applications in which conformal cooling is required, such as die casting applications.

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/