Plastic Mold Steels

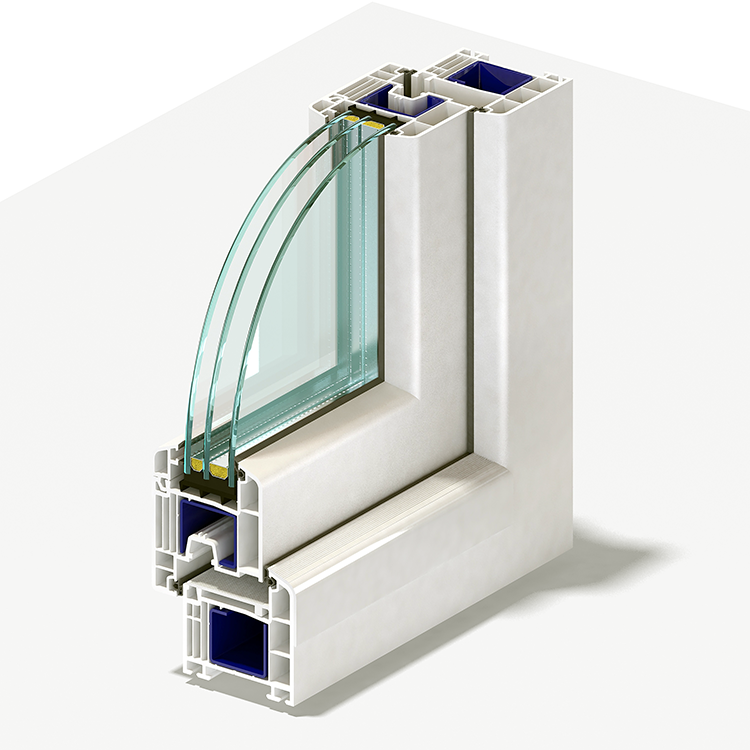

From EDRO’s flagship stainless holder material RoyAlloy, to Böhler’s unique insert steels, our premium stainless steels are able to withstand the toughest requirements.

From EDRO’s flagship stainless holder material RoyAlloy, to Böhler’s unique insert steels, our premium stainless steels are able to withstand the toughest requirements.

Grade | Description | Supplied Hardness (HRC) | Polishability | Corrosion Resistance | Wear Resistance | Toughness | Machinability |

Prehardened Stainless Steels | |||||||

400 series stainless, excellent machinability and dimensional stability. | ~32 | ||||||

Resulfurized 15-5 stainless, high machinability and corrosion resistance. | ~38 | ||||||

400 series stainless, excellent dimensional stability and polishability. | ~38 | ||||||

Modified DIN 1.2316, high polishability and dimensional stability. | ~38 | ||||||

Grade | Description | Supplied | Polishability | Corrosion Resistance | Wear Resistance | Toughness | Machinability |

Hardenable Stainless Steels | |||||||

AISI 420 ESR stainless. | ~52* | ||||||

Modified 420 ESR Stainless, superior toughness, excellent thermal | ~48* | ||||||

Modified 440B stainless, remelted. High wear resistance. | ~54* | ||||||

Powder Metallurgical modified | ~54* | ||||||

Powder Metallurgical stainless grade, extremely high wear resistance. | ~60* | ||||||

Steel properties should only be compared within their own category | |||||||

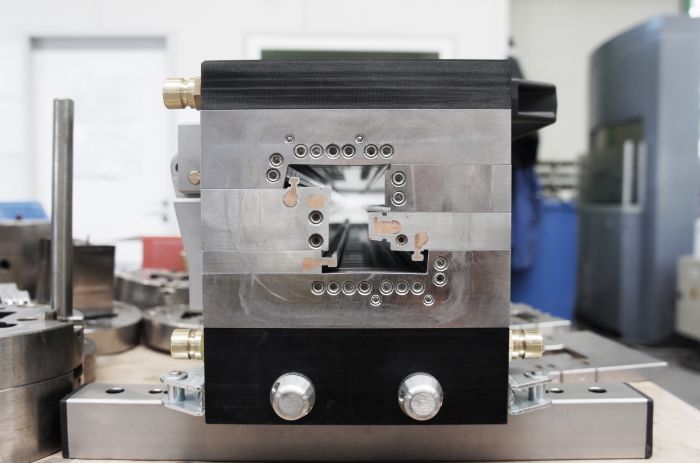

RoyAlloy was developed by EDRO to provide superior performance in all important areas of manufacturing and operation for the plastic and rubber mold tooling industries. Extensive machining trials have shown that this material is readily machined, provides excellent surface finishes and thread quality. Special production procedures provide superior surface quality and flatness. Bend tests have demonstrated that this material can tolerate moderate amounts of cold flattening without breakage. Heat treating and microstructure of the material provides excellent dimensional stability after machining, without need for stress relieving or excess stock oversize. RoyAlloy is also suitable for texturing and photoetching.

RoyAlloy is a 400 series martensitic stainless steel supplied prehardened.

Corrosion Resistance

![]()

Machinability Supplied

![]()

Polishability

![]()

Toughness

![]()

Wear Resistance

![]()

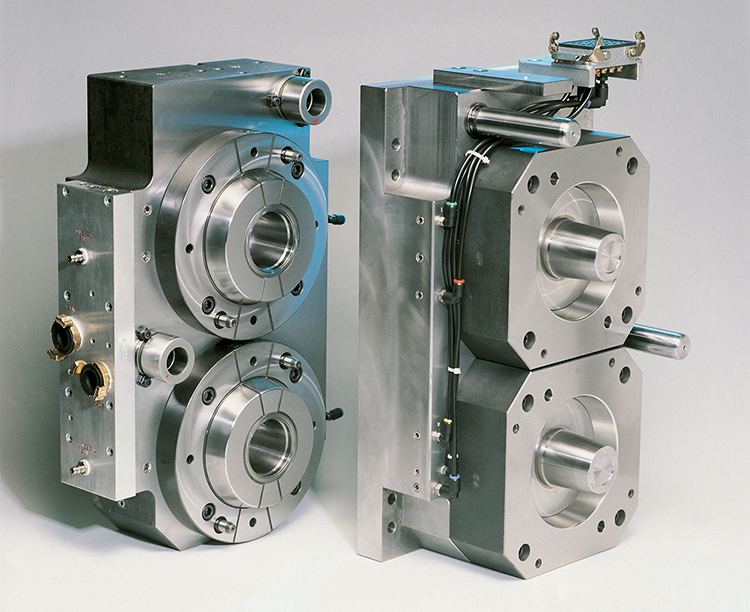

Ultrachem’s excellent corrosion resistance reduces both mold maintenance costs and productions costs. Consistently high molding productivity is assured since cooling channels are not subjected to corrosion and loss of cooling efficiency.

Ultrachem is recommended for use in long life molds subjected to severe working conditions including corrosive materials and atmospheres, high stressed and indentation experienced in today’s fast cycling molding and extrusion operations.

Corrosion Resistance

![]()

Machinability Supplied

![]()

Polishability

![]()

Toughness

![]()

Wear Resistance

![]()

EDRO400™ is a remelted 400 series martensitic stainless steel supplied prehardened to approximately 40 HRC (375 HB).

EDRO400™ was developed as an improved stainless grade providing excellent polishability combined with good corrosion resistance, consistent hardness, enhanced machinability, superior dimensional stability, and good ductility and toughness within a prehardened range of 38 – 42 HRC.

EDRO400 is a 400 series martensitic remelted stainless steel supplied prehardened.

Corrosion Resistance

![]()

Machinability Supplied

![]()

Polishability

![]()

Toughness

![]()

Wear Resistance

![]()

The New Classic

BÖHLER M303 EXTRA is a corrosion resistant martensitic chromium steel, offering excellent toughness, corrosion and wear resistance. It is characterized by improved machinability and polishability.

BÖHLER M303 was developed for improved homogeneity compared to 1.2316 and offers superior toughness as well as improved thermal conductivity, combined with good wear resistance.

Corrosion Resistance

![]()

Machinability Supplied

![]()

Polishability

![]()

Toughness

![]()

Wear Resistance

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

BÖHLER M310 ISOPLAST is an advanced martensitic stainless chromium steel for plastic molds. Equivalent to the widely used 420ESR stainless insert steel, BÖHLER’s version provides improved wear resistance and better homogeneity of the material.

Thanks to electroslag remelting, special measures in hot forming and heat treatment, and optimization of chemical composition the BÖHLER grade M310 ISOPLAST offers numerous advantages.

Corrosion Resistance

![]()

Machinability Supplied

![]()

Polishability

![]()

Toughness

![]()

Wear Resistance

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

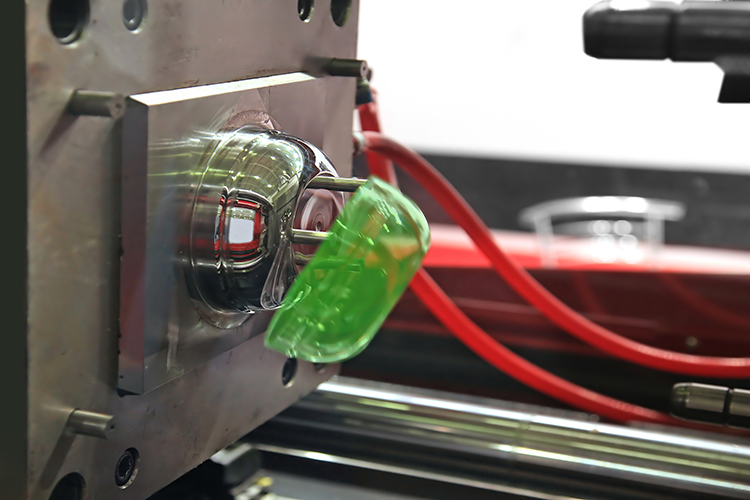

A stainless steel with excellent thermal conductivity and no compromise on toughness!

Working with tooling specialists, BÖHLER has developed a material with revolutionary composition, manufactured via a new melting technology, results in the best polishability, outstanding toughness, very good corrosion resistance and improved thermal conductivity.

This collection of positive attributes guarantees cost savings by considerably reducing the effort needed for polishing to a mirror finish, guaranteeing longer mold life, (thus ensuring reduced need for new tools, reducing maintenance and repair time, and providing security against fracture) and increasing productivity by shortening cycle times.

Thus, the production of mirrored finish molds means no more risk for the mold maker.

Corrosion Resistance

![]()

Machinability Supplied

![]()

Polishability

![]()

Toughness

![]()

Wear Resistance

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

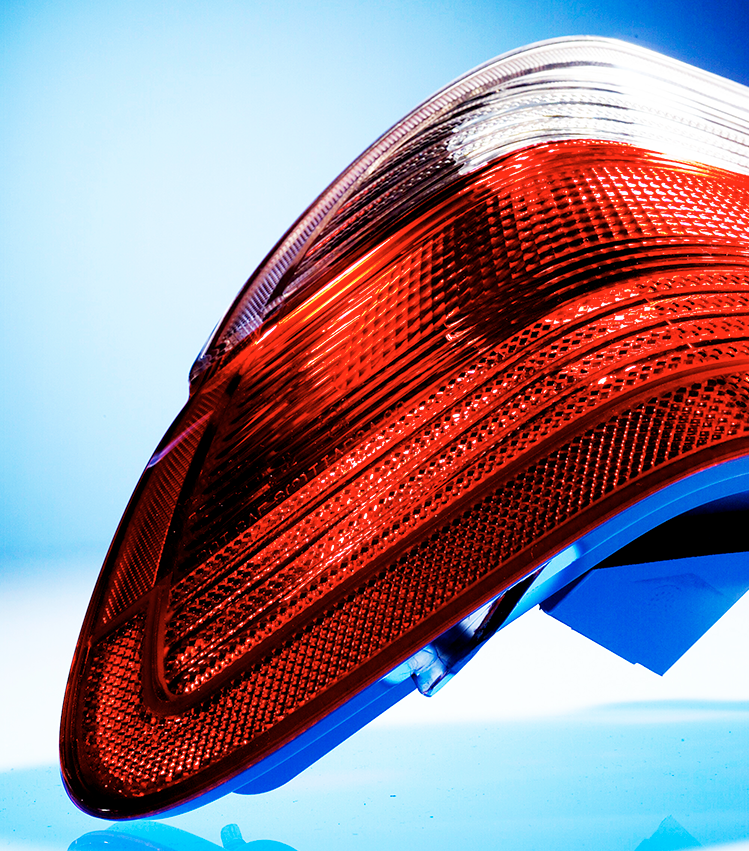

BÖHLER M340 ISOPLAST is a modified version of high chrome 440B/440C type steels, featuring a remelting process to increase toughness and prevent cracking.

An increase in productivity in mold-making can be achieved by using mold steels with materials properties trimmed specifically towards the intended use.

Due to the increased share of glass-fiber reinforced plastics, BÖHLER M340 ISOPLAST is also increasingly suitable for this kind of process, combining excellent wear resistance with suitable toughness.

Corrosion Resistance

![]()

Machinability Supplied

![]()

Polishability

![]()

Toughness

![]()

Wear Resistance

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

BÖHLER M368 MICROCLEAN is a martensitic chromium steel produced with powder metallurgy. Due to its alloying concept this steel offers high wear resistance, high toughness and high corrosion resistance – the perfect combination for best application properties.

Corrosion Resistance

![]()

Machinability Supplied

![]()

Polishability

![]()

Toughness

![]()

Wear Resistance

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

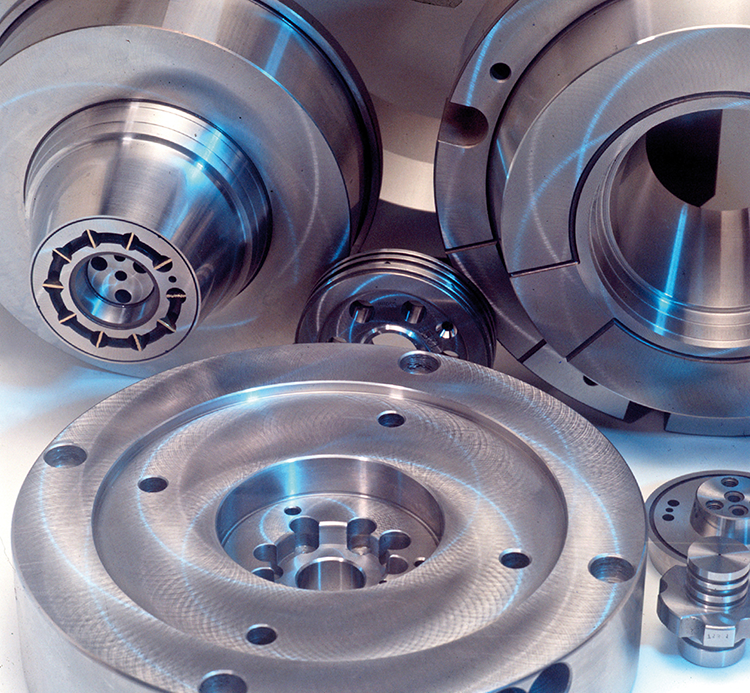

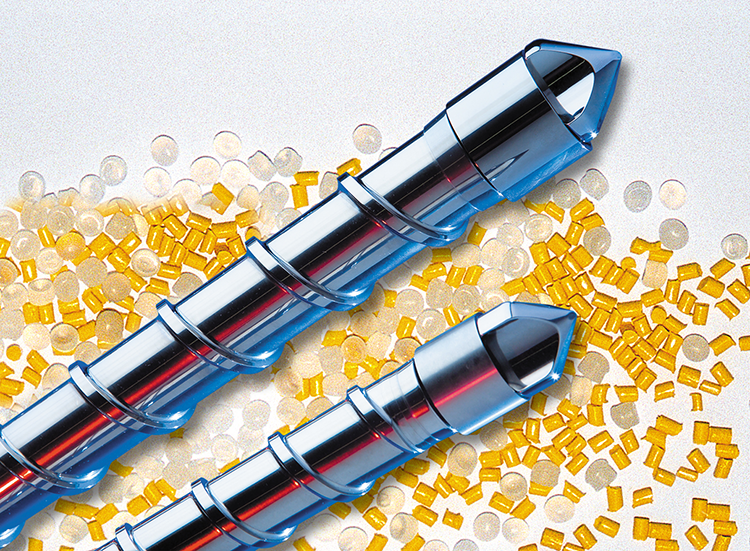

M390 Microclean is considered the steel of choice for highly wear resistance and stainless applications such as medical insert cores, extrusion screws as well as well as molding of abrasive plastics.

It’s also the steel of choice for high end knife-makers!

Corrosion Resistance

![]()

Machinability Supplied

![]()

Polishability

![]()

Toughness

![]()

Wear Resistance

![]()

Due to its outstanding property profile BÖHLER M390 MICROCLEAN is used in fields aside from plastics processing industry, such as:

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/