PLASTIC MOLD STEELS

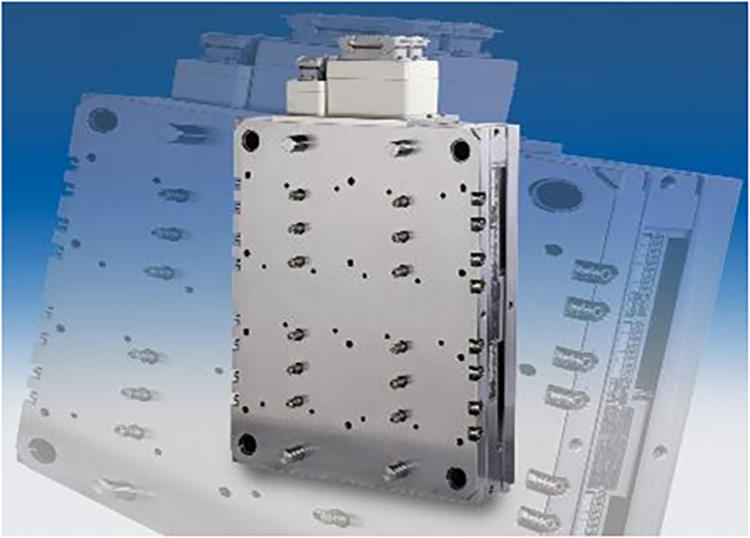

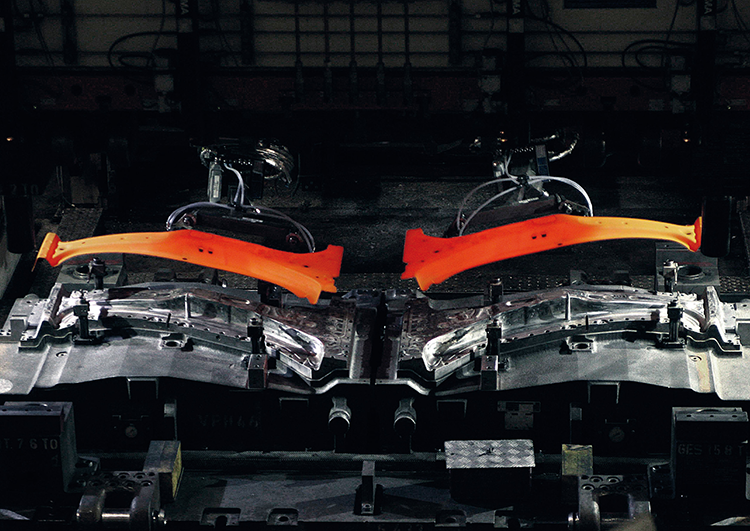

Our Stainless Mold Steels have been designed, developed and refined specifically to provide the optimum solution for the most demanding tooling applications in today’s expanding plastic mold market.

Our Stainless Mold Steels have been designed, developed and refined specifically to provide the optimum solution for the most demanding tooling applications in today’s expanding plastic mold market.

Grade | Description | Supplied Hardness (HRC) | Polishability | Thermal Conductivity | Wear Resistance | Toughness | Machinability |

Prehardened Non Stainless Steels | |||||||

Modified 4130, superior machinability and dimensional stability. | ~30 | ||||||

Prehard, precipitation hardened grade with high machinability. | ~40 | ||||||

AISI P20, good machinability and dimensional stability. | ~32 | ||||||

AISI P20+Ni remelted under vacuum, high polishability and toughness. | ~38 | ||||||

Grade | Description | Supplied Hardness (HRC) | Polishability | Thermal Conductivity | Wear Resistance | Toughness | Machinability |

Hardenable Non Stainless Steels | |||||||

Premium AISI H11 ESR. | 48-50 | ||||||

Premium AISI H13 ESR. | 44-52 | ||||||

Modified H13 ESR, outstanding toughness higher hardness levels. | 52-57 | ||||||

Vacuum remelted Mod. 1.2367 | 54 max | ||||||

Maraging 300 grade melted/remelted under vacuum. | 53-55 | ||||||

AISI A11, Powder metallurgical grade, extremely high wear resistance. | 58-64 | ||||||

Premium AISI S7 ESR | 56-60 | ||||||

P1-FM™ is an improved low alloy holder steel designed specifically for plastic and rubber molding applications. Chemical composition and thermal treatments provide physical properties and microstructures designed to provide, excellent machinability, dimensional stability, safe weld repair, and reduced mold maintenance costs.

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

BÖHLER M261 is a precipitation-hardening steel grade for plastic molds, featuring excellent machinability in the as-supplied, i.e. solution annealed and aged, condition. There is no need for an additional heat treatment, significantly shortening the throughput time.

.

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

P20 MQ is a vacuum-degassed, ladle refined, Cr—Ni-Mo-alloyed steel which is supplied in the hardened and tempered condition, offering the following benefits:

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

BÖHLER M268 VMR is a hardened and tempered plastic mold steel with excellent cleanliness for best polishability. The hardness is constant over the entire cross-section of the steel block, even at large sizes, due to the addition of nickel.

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

Hot work tool steel offering high impact strength, excellent hot tensile properties, and outstanding air hardenability, admits water cooling.

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

Hot work tool steel featuring excellent hot tensile properties, high hot wear resistance, adequate toughness and heat checking resistance; admits water cooling.

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

Hot work tool steel with high hardness, specially developed for use in warm forging applications or for forging dies. BÖHLER W360 ISOBLOC has a significantly higher toughness than 1.2367 ESR – at a higher hardness.

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

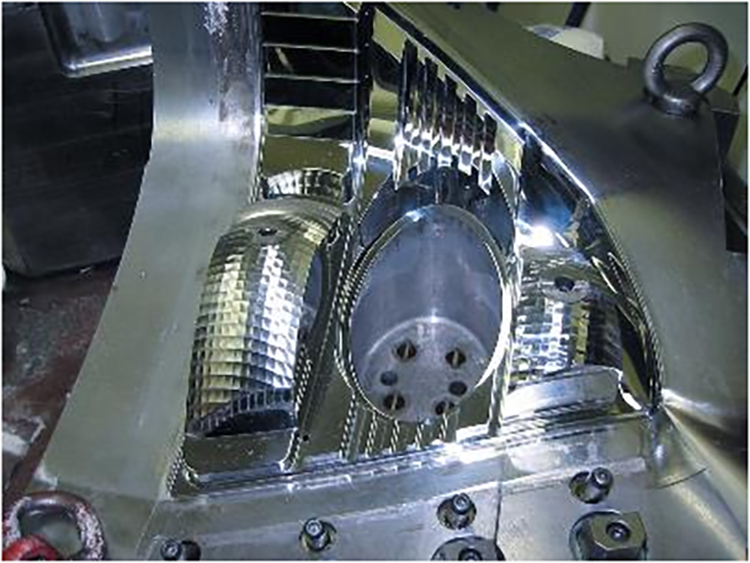

The most important factors, among others, which can result in a lowering of production costs are a long tool life and low maintenance and stand still costs. This is achieved in practice by using tool materials which, for example, are highly homogenous and have a high micro-cleanliness, causing a significant delay in the onset of heat checking.

In addition, tool life can be dramatically increased in some applications by taking advantage of high thermal stability or inherent toughness. Along with longer tool life, using these modified tool materials gives users numerous supplementary benefits arising from the following factors:

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

W720 VMR is a ultra-high-strength maraging steel. In contrast to heat treatable steels its outstanding tensile properties are not due to a hardened structure with relatively high carbon content, but to precipitation of intermetallic phases from a ductile nickel bearing matrix containing almost no carbon. This results in the following advantages: High tensile strength and excellent yield point ratio, satisfactory toughness (reduction of area, elongation, impact strength, fracture toughness) even at low temperatures, superior notched tensile strength and heat checking resistance, practically no size change in heat treatment, no decarburization, no cracking, full hardening even in sizes above average. Convenient machinability in the solution annealed condition (machining is also possible in the precipitation-hardened condition). Good cold forming properties owing to reduced susceptibility to work hardening, eminent weldability, simple heat treatment at low temperatures.

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

Powder-metallurgical produced cold work tool steel with extremely high wear resistance, good toughness and high compressive strength.

3rd Generation PM Technology

The latest generation of powder metal technology enables Bohler to manufacture a cleaner and finer powder then any other producer in the world today. The result is a significant increase in toughness and a more uniform carbide distribution.

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

EDRO S7 ESR is a chromium-molybdenum shock resistant steel characterized by high toughness and high impact resistance.

These benefits, coupled with the high wear resistance offer the molder low-maintenance, long-life molds for the greatest overall molding economy.

EDRO S7 ESR is produced using the ElectroSlag-Refining (ESR) technique, resulting in an extremely fine and consistent micro-structure with superior cleanliness.

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()