BOHLER offers a variety of premium Hot Work Tool Steel grades that can improve performance in all aspects of Forging applications. It addresses issues such as cracking, hot wear, plastic deformation, and heat checking.

Forging Materials

Hot work tool steel featuring excellent hot tensile properties, high hot wear resistance, adequate toughness and heat checking resistance; admits water cooling.

Characteristics

- Great toughness

- Good wear resistance

- Good heat checking resistance

Technical Specifications

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

Applications

- Heavy duty hot work tools and dies, mainly for light alloy processing

- Mandrels, dies, and containers for metal tube and rod extrusion

- Hot extrusion equipment

- Tools and dies for the manufacture of hollow bodies, screws, rivets, nuts and bolts

- Die casting equipment, forming dies, die inserts, hot shear blades, and plastic molding dies.

Material Numbers

- DIN: 1.2344

- UNS: T20813

- EN: X40CrMoV5-1

- AISI: H13

- STN: 19 554

Executions

- Round Bar

- Saw Cutting

- Flat Plate

- Saw Cutting

- 6 Side Processing

- Surface Grinding

- Gun Drilling

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

Downloads

Hot work tool steel featuring excellent hot tensile properties, high hot wear resistance, adequate toughness and heat checking resistance; admits water cooling.

Characteristics

- Great toughness

- Good wear resistance

- Good heat checking resistance

Technical Specifications

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

Applications

- Heavy duty hot work tools and dies, mainly for light alloy processing

- Mandrels, dies, and containers for metal tube and rod extrusion

- Hot extrusion equipment

- Tools and dies for the manufacture of hollow bodies, screws, rivets, nuts and bolts

- Die casting equipment, forming dies, die inserts, hot shear blades, and plastic molding dies.

Material Numbers

- DIN: 1.2344

- UNS: T20813

- EN: X40CrMoV5-1

- AISI: H13

- STN: 19 554

Executions

- Round Bar

- Saw Cutting

- Flat Plate

- Saw Cutting

- 6 Side Processing

- Surface Grinding

- Gun Drilling

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/

Downloads

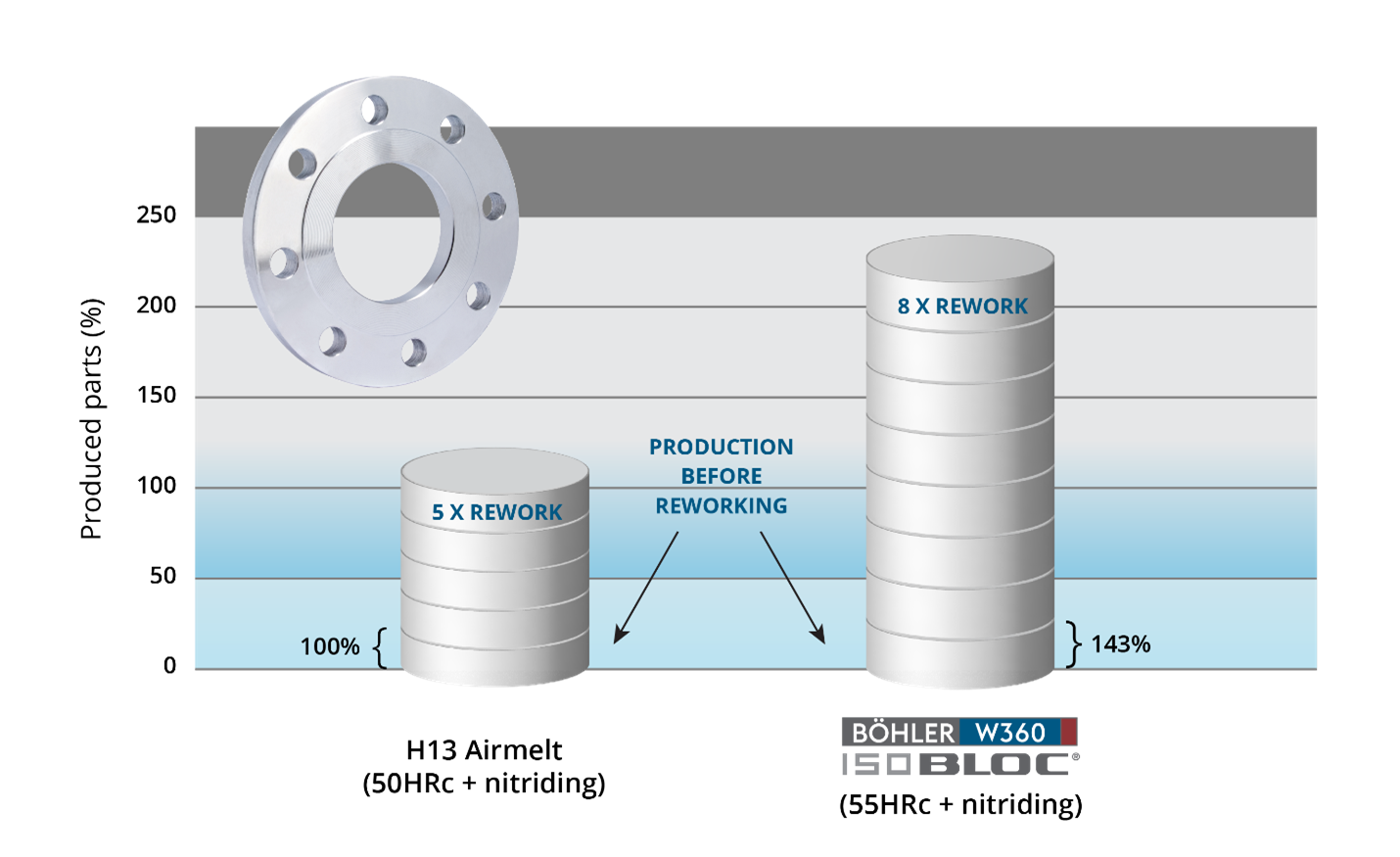

Hot work tool steel with high hardness, specially developed for use in warm forging applications or for forging dies. BÖHLER W360 ISOBLOC has a significantly higher toughness than 1.2367 ESR – at a higher hardness.

Characteristics

- High hardness (recommended in use: 52 – 57 HRc)

- Exceptional toughness

- High temper resistance

- Good thermal conductivity

- Can be cooled with water

- Homogeneous microstructure

Technical Specifications

Polishability

![]()

Thermal conductivity

![]()

Wear resistance

![]()

Toughness

![]()

Machinability

![]()

Applications

- Dies and punches in warm and hot forging

- Tooling for high speed presses

- Toughness-critical cold work application

- Extrusion tooling, e.g. dies

- Core pins and inserts in die-casting dies

- Specific applications in the plastic processing sector

Executions

- Round Bar

- Saw Cutting

- Flat Plate

- Saw Cutting

- 6 Side Processing

- Surface Grinding

- Gun Drilling

For details on BÖHLER tool steels please visit:

https://www.us.bohler.com/en/